Essential Benefits Why Aluminum Casting Company is Transforming Modern Manufacturing

Discover the Advantages of Aluminum Casting in Modern Manufacturing

Aluminum casting has become a crucial procedure in contemporary production. Its light-weight yet robust nature presents significant advantages for various industries. The ability to accomplish complex layouts and preserve tight tolerances contributes to its appeal. Aluminum Foundry. Additionally, the cost-effectiveness and environmental advantages make it a sustainable option. As makers look for cutting-edge solutions, the role of aluminum casting proceeds to advance. What details applications and advantages wait for exploration in this dynamic field?

Light-weight Yet Strong: The Advantages of Aluminum

Although several products are made use of in production, aluminum attracts attention as a result of its impressive mix of light-weight residential or commercial properties and remarkable strength. This distinct feature makes aluminum an optimal option for different applications, particularly in industries such as auto, aerospace, and construction. Its reduced thickness permits simpler handling and transport, adding to minimized energy intake throughout production and setting up procedures.

Furthermore, aluminum's strength-to-weight ratio is remarkable, making it possible for suppliers to produce resilient elements without including unneeded bulk. This characteristic is particularly useful in sectors where weight reduction can cause improved gas effectiveness and overall performance. Furthermore, aluminum's resistance to deterioration enhances the durability of items, even more strengthening its appeal in modern-day manufacturing.

Inevitably, the lightweight yet solid nature of aluminum placements it as a recommended material, promoting advancement and effectiveness across multiple markets. Suppliers significantly recognize that these benefits can result in substantial advancements in style and performance.

Precision and Intricacy in Layout

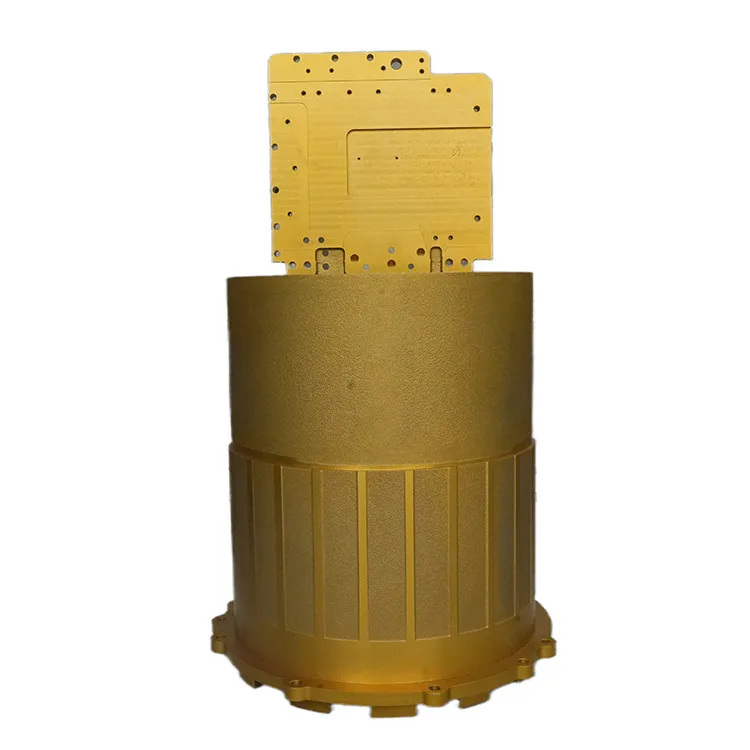

As suppliers embrace the abilities of aluminum casting, they discover brand-new avenues for precision and complexity in layout. This manufacturing procedure permits the development of intricate shapes and thorough features that typical approaches often struggle to attain. The fluidity of molten aluminum enables it to fill complex mold and mildews, causing parts with limited tolerances and fine surface finishes.

This precision is specifically advantageous in industries such as aerospace and automobile, where precise specs are necessary for performance and safety. Aluminum casting additionally suits cutting-edge layouts that enhance performance without jeopardizing structural honesty.

Cost-Effectiveness and Performance

Cost-effectiveness and effectiveness are extremely important factors to consider for makers exploring aluminum casting as a production approach. Aluminum casting deals considerable price benefits as a result of its lower product costs contrasted to other steels (aluminum casting). The light-weight nature of aluminum minimizes delivery and handling expenditures, and its superb thermal conductivity permits for quicker cooling times throughout the casting process, boosting overall manufacturing rate

Moreover, aluminum's flexibility makes it possible for makers to create intricate forms and styles, minimizing the requirement for additional machining or setting up. This streamlining of production not just decreases labor costs yet additionally shortens preparations, allowing companies to respond promptly to market needs.

The toughness and internet corrosion resistance of aluminum spreadings add to longer item life-spans, minimizing replacement expenses over time. Consequently, manufacturers can accomplish a balance of high-grade outcome and lowered operational expenses, making aluminum casting a significantly attractive choice in contemporary production.

Environmental Sustainability of Aluminum Casting

Aluminum casting stands out as an environmentally lasting manufacturing choice, especially due to its recyclability and minimized environmental footprint. The process permits the reliable use aluminum, a product that can be reused forever without losing its properties. This characteristic considerably lowers the demand for virgin aluminum, consequently saving natural deposits and minimizing power intake connected with extraction and handling.

Applications Throughout Industries: From Automotive to Aerospace

While diverse markets continue to look for ingenious materials for manufacturing, aluminum casting has actually shown to be a functional solution across industries such as automobile and aerospace. In the vehicle industry, aluminum castings add to light-weight lorry layouts, boosting gas efficiency and performance. Elements like engine blocks, transmission housings, and wheels gain from aluminum's strength-to-weight proportion.

In aerospace, aluminum casting plays a substantial role in creating complex parts that call for high longevity and low weight. Aircraft components such as braces, touchdown gear, and structural frames utilize aluminum for peak performance and safety and security.

The flexibility of aluminum casting permits it to cater to various other sectors, including customer electronics, aquatic, and commercial machinery. This convenience not just fulfills the details demands of numerous applications yet also sustains ongoing advancement in producing processes. Because of this, aluminum casting stays an essential gamer in modern-day production across countless industries.

Regularly Asked Questions

Exactly How Does Aluminum Casting Contrast to Other Steel Casting Procedures?

Aluminum casting deals superior strength-to-weight proportions, faster air conditioning rates, and look at this site exceptional rust resistance compared to various other metal casting procedures. These advantages make it optimal for various applications, enhancing effectiveness and performance in manufacturing.

What Are the Common Lead Times for Aluminum Casting Projects?

Typical preparation for aluminum casting jobs range from two to eight weeks, depending on elements such as intricacy, order dimension, and manufacturing ability. Effective planning can help reduce hold-ups and boost task timelines.

Can Aluminum Casting Be Utilized for Intricate Designs?

Aluminum casting can undoubtedly accommodate intricate layouts. Aluminum Foundry. Its fluidness enables in-depth patterns and forms, making it suitable for intricate components in various markets. This convenience go to my site improves design flexibility while preserving architectural honesty and performance

What Post-Processing Options Are Offered After Aluminum Casting?

Post-processing choices for aluminum casting consist of machining, brightening, surface area therapies, anodizing, and welding. These methods improve the surface, boost dimensional accuracy, and boost rust resistance, thereby maximizing the last item's performance and visual appeal.

Just How Do Temperature Level Changes Affect Aluminum Casting Quality?

Temperature modifications greatly impact aluminum casting quality by impacting fluidness, solidification prices, and prospective flaws. Fast cooling can lead to enhanced brittleness, while extreme heat might create bending or insufficient dental filling of mold and mildews during casting.

Aluminum casting has actually emerged as a critical process in contemporary manufacturing. As makers accept the abilities of aluminum casting, they discover brand-new avenues for precision and complexity in design. Aluminum casting processes usually produce fewer greenhouse gas exhausts contrasted to other steel casting approaches. While diverse markets proceed to seek innovative materials for production, aluminum casting has shown to be a functional service throughout markets such as automotive and aerospace. In the vehicle industry, aluminum spreadings contribute to lightweight car designs, enhancing gas efficiency and performance.